Black Hawk Parts for Beginners

Table of Contents7 Easy Facts About Black Hawk Parts ExplainedThe Ultimate Guide To Black Hawk PartsBlack Hawk Parts - An OverviewGet This Report on Black Hawk Parts

KAMAN K-1200 K-Max synchropter In a side-by-side blades setup, two straight, counter-rotating rotors are placed side-by-side on a helicopter (or transverse rotorcraft). black hawk parts. The anti-torque impact is offered by the opposing turning of the two main blades. The side-by-side setup is just one of the feasible trip setups of a tilt-rotor airplane, when the blades are in the vertical placement to give upright lift.It is crucial that components are created and finished in a right fashion. As a helicopter spare components dinner in the USA, Jones Metal Products is below to develop and also finish helicopter components in an exact and also timely way. Jones Metal Products has over 95 years in the hydroforming sector, a procedure that we use for a selection of parts in the aerospace and defense sectors.

As a helicopter parts distributor, Jones Steel Products regularly invites outside organizations in for appropriate certifications. These outdoors companies observe and validate the numerous processes that we have on offer where we are making continuous breakthroughs in composite manufacturing of helicopter parts. ISO 9001:2015 without Design This certification connections to our top quality management system.

When it comes to being a trusted as well as valued helicopter components supplier, making advances in composite manufacturing of helicopter parts comes with the area. The processes where we make helicopter parts are constantly being enhanced upon by our experienced team. Our team of designers, developers, as well as metalworkers have been innovating our services since the 1920s.

Fascination About Black Hawk Parts

They can even help you to recreate older helicopter parts that stem from discontinued runs all while restraining with our high criteria of high quality and also regular manufacturing. Hydroforming, Rubber pad forming, Warmth treating, Stretch creating As a top helicopter components producer, Jones Metal Products is happy to collaborate with customers in the aerospace, protection, and airplane industries.

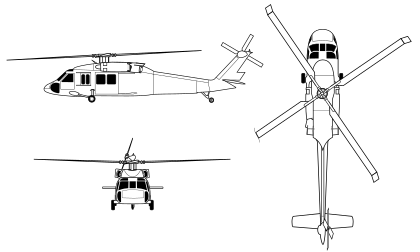

Helicopters are identified as rotating wing aircraft, and their rotating wing is typically referred to as the major blades or just the blades. Unlike the a lot more typical fixed wing airplane such as a sporting activity biplane or an airplane, the helicopter is capable of direct upright liftoff and also touchdown; it can also hover in a fixed setting.

The autogiro he ultimately designed bundled features of both the helicopter as well as the airplane, although it looked like the More Info last even more. The autogiro had a rotor that functioned something like a windmill. When established in activity by cabbing on the ground, the rotor might create supplemental lift; nonetheless, the autogiro was powered mainly by a standard aircraft engine.

Fascination About Black Hawk Parts

To steer a helicopter, the pilot must readjust the pitch of the blades, which can be established 3 methods. In the collective system, the pitch of all the blades affixed to the rotor is identical; in the cyclic system, the pitch of each blade is created to rise and fall as the blades rotates, as well as the 3rd system makes use of a mix of the very first next 2.

A relevant trouble happens since, as the helicopter relocates ahead, the lift below the blades that go into the airstream first is high, but that beneath the blades on the contrary side of the blades is low. The net result of these issues is to destabilize the helicopter. Usually, the ways of compensating for these unpredictable variants in lift as well as drag is to manufacture adaptable blades attached to the rotor by a joint.

Torque, one more problem related to the physics of a revolving wing, triggers the helicopter fuselage (cabin) to revolve in the opposite direction from the blades, particularly when the helicopter is relocating at reduced speeds or hovering. To counter this reaction, several helicopters utilize a tail blades, a subjected blade or ducted follower installed on completion of the tail boom commonly seen on these craft.

He tried out for more than twenty years and also lastly, in 1939, flew his initial flight in a craft called the VS 300. Connected to the ground with long ropes, his craft flew no greater than 50 feet off the ground on its very first a number of trips. Even after visit our website that, there were troubles: the craft flew up, down, and laterally, yet not forward.

What Does Black Hawk Parts Do?

as well as asked to try among their new primary structure workplace computers. By 1951, Parsons was try out having the computer system's calculations really lead the maker device. His suggestions were ultimately turned into the computer-numerical-control (CNC) machine device industry that has actually transformed contemporary production approaches. 1 Each private tubular part is reduced by a tube cutting maker that can be rapidly established to create different, exact sizes and also defined batch quantities.

For apart from small bends, tubes are loaded with molten salt silicate that hardens and eliminates kinking by causing television to flex as a solid bar. The supposed water glass is then removed by positioning thebent tube in boiling water, which melts the internal material. Tubes that should be curved to match body contours is fitted over a stretch creating device, which stretches the steel to an exactly contoured form.

The latter process requires injecting wax or an alloy with a reduced melting point right into a mold or pass away. When the design template has been created, it is dipped in molten steel as sometimes as needed to achieve the density preferred. When the component has actually dried, it is warmed to make sure that the wax or alloy will thaw as well as can be poured out - black hawk parts.